SMARC Module

(스마크 모듈)

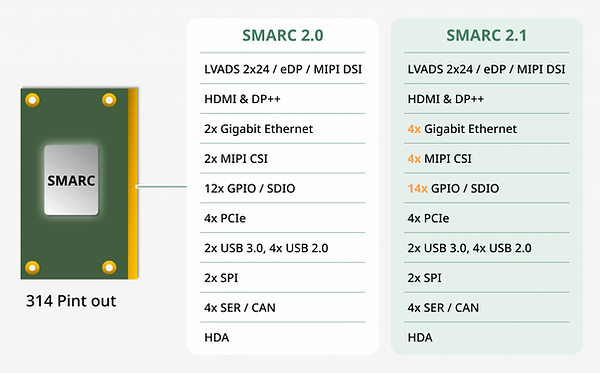

SMARC ( "Smart Mobility ARChitecture")는 고성능 벤치 마크와 함께 저렴하고 전력 효율적인 옵션이 필요한 사용자에게 이상적인 매우 다양한 소형 폼 팩터 컴퓨터 온 모듈입니다. 이 SMARC 모듈 크기는 로우 프로파일 314 핀 0.5mm 피치 직각 커넥터와 결합되는 314 개의 엣지 핑거와 함께 82mm x 50mm 및 82mm x 80mm로 제공됩니다.

이러한 SMARC 모듈은 광범위한 수준의 통합 및 전력 효율적인 처리 기능을 갖추고 있고, 산업 자동화, 운송 및 통신 장비 응용 분야에 특히 적합하지만, 포괄적인 사용 목록은 아닙니다.

314개의 핀으로 구성된 SMARC 2.1 커넥터는 PCI Express 레인, 2개의 추가 MIPI CSI 인터페이스 및 추가 GPIO를 지원하므로 그래픽, 카메라, 사운드, 네트워크 및 무선 인터페이스 옵션과 함께 다양한 선택이 가능한 SMARC 설계가 가능합니다. 이를 통해 SMARC는 더욱 강력한 멀티미디어 애플리케이션을 추구할 수 있으며 디지털 전자 사이니지, 산업용 얇고 컴팩트한 가전 제품 및 HMI에 더 적합합니다.

SMARC 디자인 장점

-

ARM 및 x86프로세서 기술에 기반한 에너지 절약형 SoC 프로세서

-

광범위한 비디오 인터페이스 옵션

-

12~14핀의 추가 GPIO

-

최대 4x 기가비트 이더넷

-

비전 애플리케이션을 위한 최대 4개의 MIPI CSI 카메라

-

무선 기술

사례 연구- 비전검사 시스템

고속, 고정밀 광학 이미지 검사 시스템은 머신 비전을 검사 표준 기술로 사용합니다. 이미지 처리 검사 시스템에는 호스트, 카메라, 렌즈, 광원 등이 포함됩니다. 카메라를 사용하여 물체를 촬영하고 이미지를 2차원 평면으로 분석하여 순식간에 검사가 완료됩니다. 이러한 머신 비전 검사는 기존에 광학 기기를 사용해 사람이 직접 검사하던 단점을 개선했습니다. 첨단 산업의 연구 개발, 제조 품질 관리뿐만 아니라 국방, 의료, 환경 보호, 전력 등 다양한 분야에서 활용되고 있습니다.

오늘날 산업 자동화 분야에서 무선 네트워크를 사용하는 애플리케이션은 머신 비전 시스템이 고주파 신호 손실, 전송 속도, 모듈 통합, 시스템 안정성 및 전력 소비와 같은 더 많은 설계 과제에 직면하게 합니다. 따라서 저전력 소비와 고도로 통합된 SMARC 모듈은 이 분야의 애플리케이션에 가장 적합한 솔루션을 제공합니다. SMARC 크기의 장점으로 비전 검사 시스템을 소형화할 수 있으며 카메라, 광원 등과 같은 장치의 사용을 지원하기 위해 더 많은 MIPI CSI/USB 및 DI/DO 수량을 제공합니다. SMARC 모듈형 시스템은 공장 자동화 요구사항의 빠른 변화에 대응하여 기존 플랫폼에 빠르게 통합 및 개발할 수 있으며 다양한 생산 현장에서 물체의 흉터, 먼지 등 외관 결함을 검출할 수 있습니다.